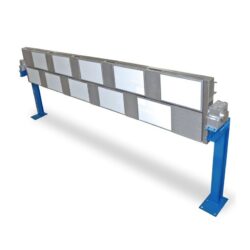

METAL SHARK® TU

Tunnel for Conveyor Installation on Bottom and Top of the Conveyed Material

Categories: Industrial Metal Detector, Flat Plate, Cassel Tags: Cassel, Metal, 金屬

Typically, the Metal Detector TU types are used in

- plastic recycling

- rubber production

- wood and paper processing

- food related industries

The TU provides the highest performance in detecting magnetic and non-magnetic metals.

Available digital controllers: METAL SHARK® 1, METAL SHARK® 2A The control box can be wall mounted or attached to the sensor.

Features & Benefits of Metal Detector TU

- No belt cut: The TU type has a divisible sensor head. This makes installation into an existing conveyor exceptionally easy. Sensor head can be installed without splitting the conveyor belt.

- Aperture height: The aperture height can be changed later on. The TU automatically calibrates certain changes in the sensor head geometry.

- HACCP and IFS compliance: Per HACCP principles, Metal Detectors are classified as critical control points and continuous checking is required to meet standards. If requested, Cassel can integrate a performance validation system (PVS) which automatically prompts the operator to test Metal Detector performance at pre-set intervals.

- Operational history: Metal contaminant detections, changes in parameter settings and other events are recorded with the date and time. Users can view the list of “incidents” on the control panel or export the log via a serial port.

- Ready for SHARKNET® software: To comply with HACCP and IFS standards, SHARKNET® enables automatic downloading of data documentation to a Windows-based PC.

- LPW option for low pressure wash-up (IP67): To obtain the IP67 rating, the METAL SHARK® controller can be housed in a double-thick stainless steel enclosure. This upgrade allows for wash-up with a low-pressure water hose.